Challenges

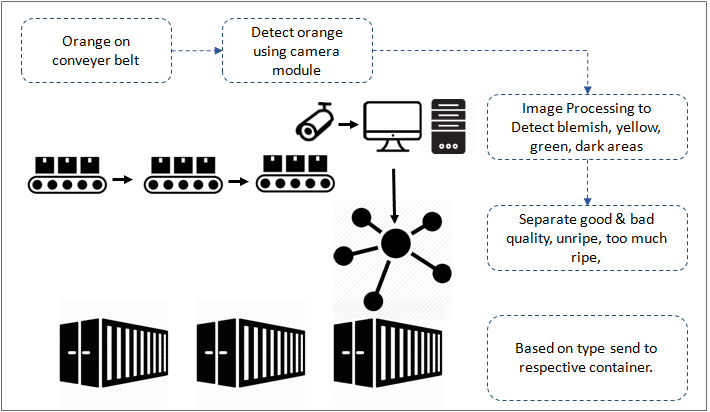

- A Spanish agricultural company wanted to be able to automatically detect grades for oranges using image processing to identify colour.

- The company needed unique hardware using a camera interface logic to run a sorting algorithm.

- The system needed to bring individual oranges into the frames of multiple cameras at the same time.

- Having graded each orange, the system would need to send the fruit to its respective container.

Xpertnest’s Solutions

- Xpertnest developed a conveyer belt system to bring the oranges into frame.

- Designed and developed a processor to implement a sorting algorithm.

- The algorithm detected blemishes and differentiated between yellow and green skin.

- Enabled the possibility of future improvements with higher end processors, optimised algorithms, and a better camera module.

Value Delivered

- Increased the accuracy and efficiency of orange sorting.

- Generated more revenue by delivering high quality fruit to the juice-making industry.

- The automation helped reducing manual labour costs.