Challenges

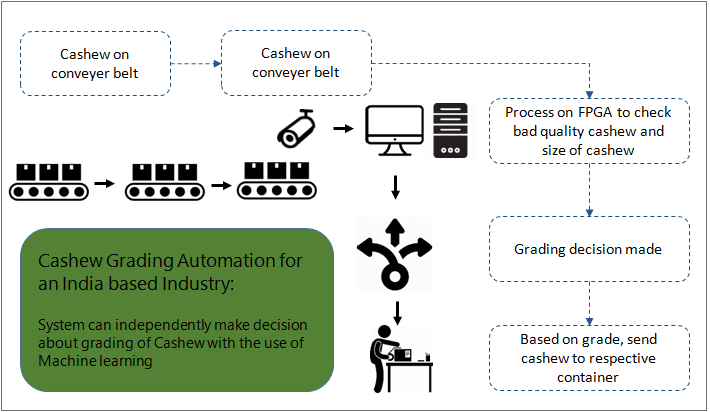

- A cashew producer in India wanted to use image processing to automatically detect cashew grades based on size and remove low quality cashews.

- The company would need new hardware with a camera interface and a unique algorithm.

- The hardware would need to process 10 cashews/second, bringing a single cashew into a camera frame at a time.

Xpertnest’s Solutions

- Designed a conveyer belt to deliver individual cashews to the camera, making processing and algorithm implementation easier and faster.

- Designed and developed an FPGA-based board to implement the algorithm and enable the high frame rate to process 10 cashews/second.

- Enabled continuous improvement with an optimised algorithm and better camera module.

Machine Learning enables independent grading of cashews

Cashew enters conveyer bel

Cashew travels down conveyor belt

FPGA-based algorithm checks cashew quality

Grading decision made

Cashew sent to suitable container based on grade

Value Delivered

- Increased the accuracy and efficiency of cashew grading.

- Increased revenues by enabling company to sell more cashews with high quality grading.

- Reduced manual labor costs through automation.